The following procedure is recommended when using Beswick pre-swage tools to compress ferrules onto Teflon®, Copper or Stainless Steel tubing.

Video Tutorial

Installation Instructions:

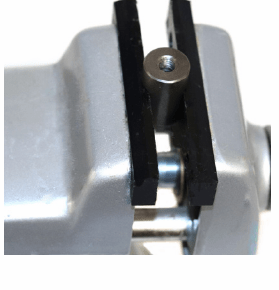

1.) Secure the pre-swage tool in a vise by clamping the vise jaws on the flats at the bottom of the pre-swage tool.

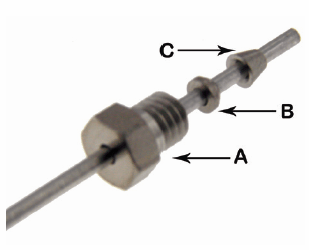

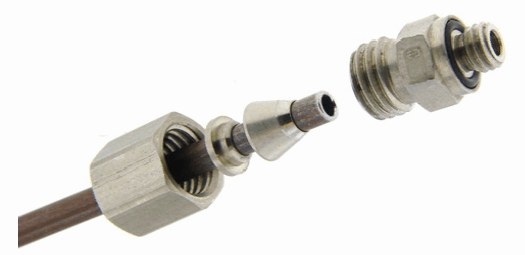

2.) Slide the top assembly of the compression fitting onto the tubing in the following order:

A) Compression Fitting Nut

B) Rear Ferrule (doughnut shape) larger diameter first (when applicable)

C) Front Ferrule (conical shape)

3.) Slide the tubing with the ferrule and nut into the base of the pre-swage tool until the tubing stops against the bottom of the fitting body.

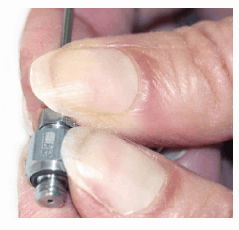

4.) Tighten the compression fitting nut in the pre-swage tool to finger-tight.

5.) Using a wrench, tighten the nut an additional 1/2 to 3/4 of a turn (180 to 270) degrees.

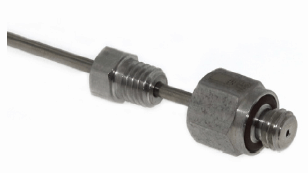

6.) Loosen the nut and remove the assembly from the pre-swage tool. The cone shaped ferrule should now be swaged onto the tubing. It may still spin a bit, but should not move up and down along the tubing. The rear ferrule (if applicable) will move freely and independently from the front ferrule. This is okay.

7.) Now insert the end of your tubing into the body of the compression fitting and push the tubing until it stops against the bottom of the fitting body.

8.) Slide the nut down to the fitting body and tighten to finger-tight.

9.) Using a pair of wrenches (one on the nut, and one to support the body of the fitting) tighten the nut an additional 1/8 to 1/4 of a turn, (45 to 90) degrees.

Ferrules- Replacements:

For all subsequent connections (after the initial swaging steps above) we recommend tightening the compression cap to 1/8 to ¼ turn past finger tight. Ferrules have a limited life and should be replaced after several connect/disconnect cycles. Ferrule part numbers are listed here.

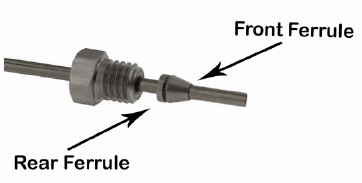

Ferrules- Design Installation:

Ferrule assembly instructions vary depending on the fitting manufacturer because the design and components are not interchangeable in most cases. Beswick two piece ferrule design (front ferrule-conical shape and rear ferrule-doughnut shaped) is utilized in the majority of Beswick compression fittings. The front ferrule is intended to create the seal between the body and tubing. The rear ferrule allows the nut to rotate without rotating the front ferrule and tubing. The function of the front and rear ferrules can vary depending on the manufacturer. With Beswick two-piece ferrules, over-tightening can cause the rear ferrule to lodge into the front ferrule.

Wrenches- Recommended:

We always recommend placing a wrench on the nut and also a wrench on the hex of the fitting body when installing compression fittings to prevent damage to the external thread. Many of our compression fittings have small threads on the fitting body, which can shear if the body is not supported during tubing installation.

Tubing- Condition:

The condition of the tubing is important to insure leak-tight connections. That is, the ends should be cut square and the surface of the tubing should be smooth (no scratches or extrusion lines).

Cleaning Operations- Secondary:

When using stainless steel compression fittings that have undergone secondary cleaning operations, it is sometimes helpful to spray the male thread on the compression body with isopropyl alcohol prior to installing the tubing. This helps to lubricate the thread, and prevent galling. The alcohol will evaporate after installation.